Capabilities

Turning Concepts into Reality

Our Capabilities

End-to-End Engineering Solutions

At JADE, we deliver precision-engineered solutions across Aerospace, Defense, Energy, and Industrial sectors. From advanced machining to complete assembly, our capabilities ensure high-quality outputs that meet global standards.

- JADE: Aerospace

- JADE: Defense

- JADE: Energy

Our Capabilities

JADE: Aerospace

JADE specializes in high-precision components and assemblies for aircraft, satellites, and jet engines. Our multi-axis CNC machines, advanced assembly systems, and certified quality processes ensure components meet the most stringent aerospace standards.

Few of the Successfully Completed Development & Pilot Projects

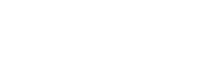

We manufacture small, precise critical components that go into the assembly of the fuselage of LCA Tejas Aircraft. Delivery to HAL supports India’s goal of self-reliant manufacturing.

Components with extremely thin finish width and low tolerance margins, supplied for an assembly that manages high-speed inflight communication on aircraft, called the Jet Wave.

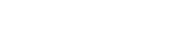

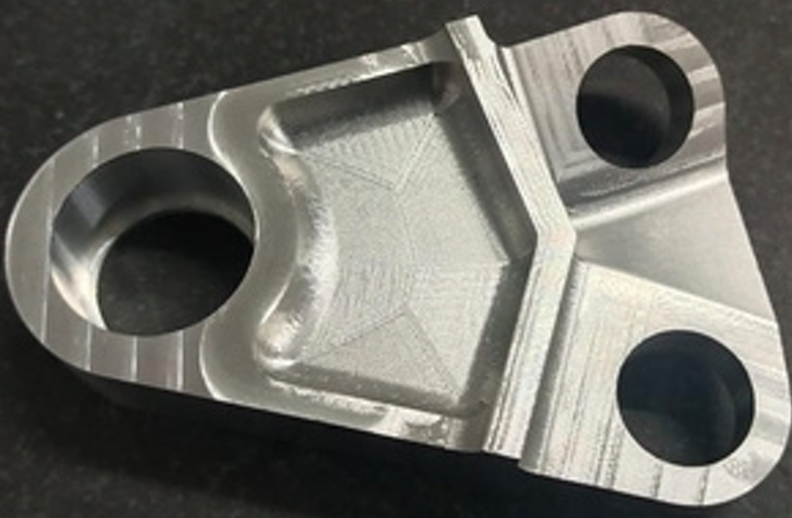

Gimbal Rings are manufactured with complex positional and geometric tolerances within 5 microns. They are crucial mechanical components for controlled multi-axis rotation in thrust vectoring and satellite/aircraft steering.

JADE: Defence

We provide mission-critical components and assemblies for land, naval, and missile defence applications. JADE partners with BHEL, L&T, and other defence organisations to deliver high-precision sub-assemblies with indigenous content and strict quality control.

Few of the Successfully Completed Development & Pilot Projects

Supplied sub-assemblies for the self-propelled artillery platform. Local production and integration achieved indigenous content up to 75% per system.

Developed 5 complicated, close-tolerance child parts requiring heat treatment and complex machining for small firearms assemblies for a large Indian conglomerate.

Supplied components for the robotic arm project. Provided gas turbine blades for the cruise missile project. Supports indigenization of missile propulsion and nuclear reactor systems.

JADE: Energy

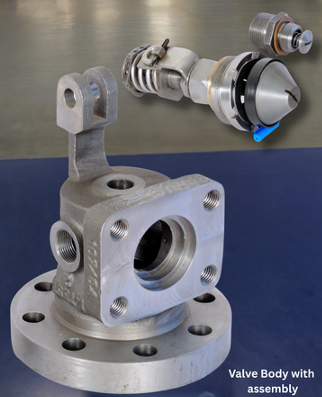

Our expertise includes machining turbine and jet engine blades, industrial valves, and energy system components. We handle challenging materials and tight tolerances with advanced technology, ensuring durability, efficiency, and reliability.

Blades (Turbines & Jet Engines)

High hardness material, challenging to machine due to work hardening.

Maintains hardness of 32 HRC at high temperatures; low thermal conductivity and rapid tool wear.

Initially machinable, becomes harder post-hardening; precise profile thickness required (20 microns).

Different blade stages with tight profile thickness tolerance (15 microns).

Manufacture, assemble, paint, and test industrial valves (sizes 1/2” to 4” / DN15–DN100) in materials like cast iron, carbon steel, and stainless steel. Serves domestic and international markets.

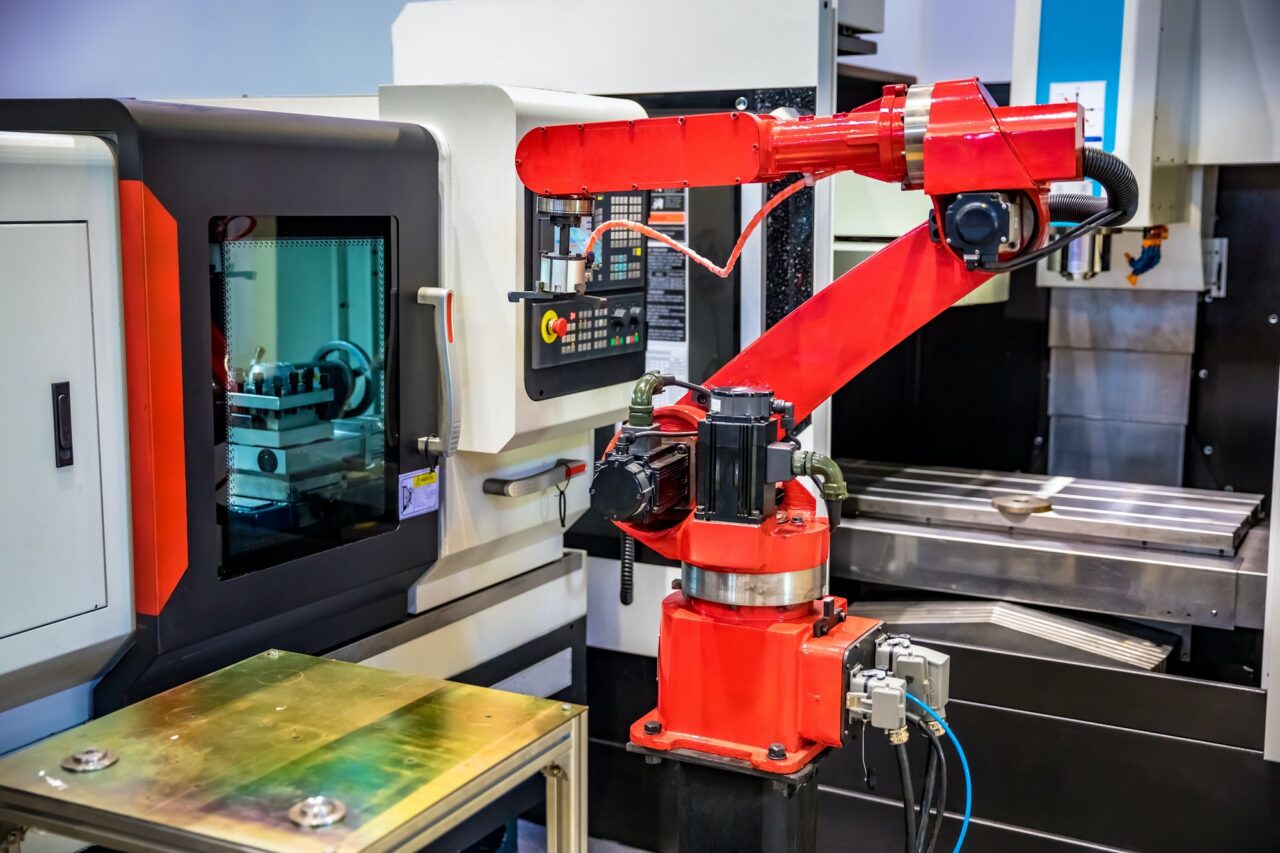

Precision components for robotic arms used in nuclear applications, ensuring high accuracy and reliability under extreme conditions.