Ahmedabad Facility

Heavy Engineering & DGAQA Certified Unit

Our Capabilities

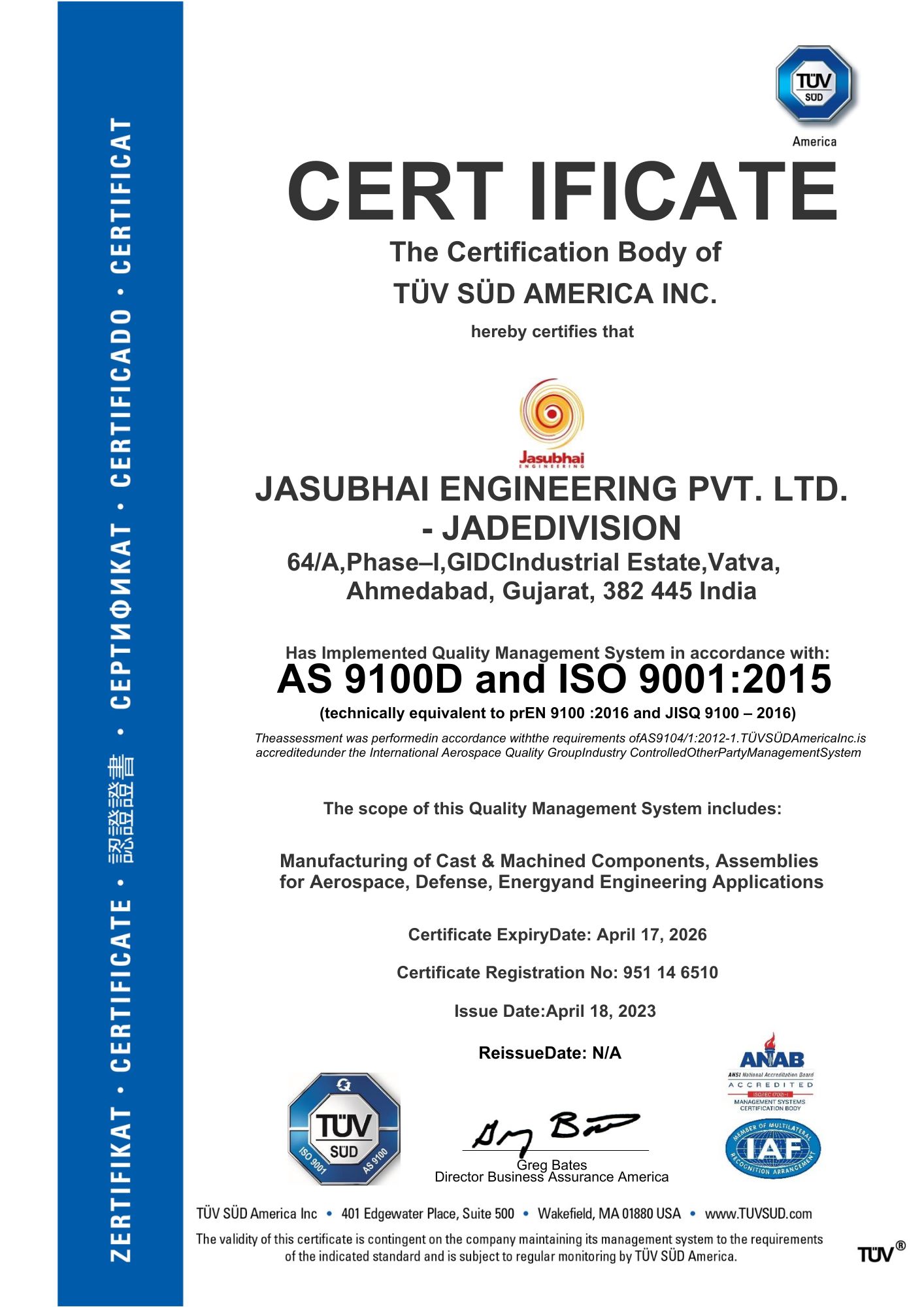

Certifications

AS9100D Certification for Aerospace Manufacturing

ISO 9001:2015 Certification for Quality Management

DGAQA Certification – Registered Defence Vendor (Ahmedabad Unit)

IBR Certification for Cast Valve Manufacturing

India Offset Partner (MoD) – Listed under Partner ID #132

Our Ahmedabad plant is among India’s elite DGAQA-approved manufacturing units, reaffirming our status as a trusted defence and aerospace component manufacturer.

Overview

The Ahmedabad Facility of Jasubhai Engineering Pvt. Ltd. – JADE Division is one of India’s premier precision manufacturing units for Aerospace, Defence, and Energy applications.

Located in the GIDC Industrial Estate, Vatwa, this 76,000 sq. ft. facility is AS9100D and ISO 9001:2015 certified, ensuring compliance with the highest global standards of quality and process management.

Our Ahmedabad plant stands among the shortlisted companies certified by DGAQA (Directorate General of Aeronautical Quality Assurance) within India, one of just around 60 approved organisations nationwide as per the 2019 DGAQA compendium.

This recognition underlines our dedication to defence-grade precision engineering, process discipline, and quality assurance.

Infrastructure Overview

Our Ahmedabad facility is equipped to deliver complete manufacturing solutions — from material handling to final inspection — under one roof.

Key Features:

CNC & Conventional Machine Shop

Multi-axis precision machining for complex aerospace and energy components.

Raw Material Storage Facility

Segregated, climate-controlled sections ensure material integrity.

Dedicated Inventory Areas

Separate allocation for each client to maintain traceability and part identity.

Component Preservation Systems

Strict humidity and contamination controls for metallic parts.

Advanced Quality & Risk Management

Project and configuration management tools are integrated into the production workflow.

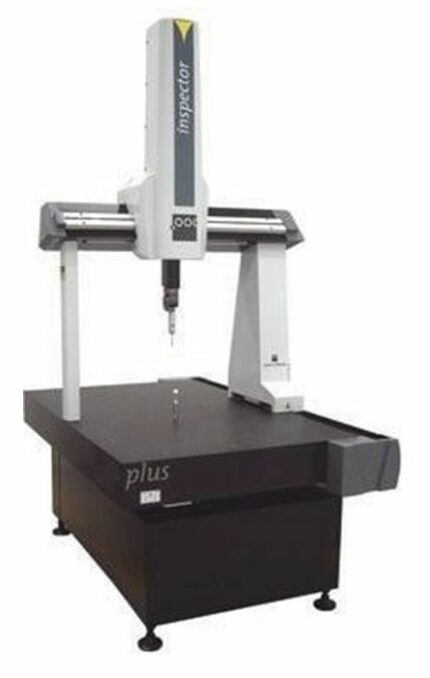

Quality Control: Zeiss Spectrum Plus CMM & NDT Testing

These systems ensure zero-defect production and full compliance with AS9100D inspection standards.

Our Machinery: DMG MORI 5-Axis, VMC & Turning Centers

Location: 64/A, GIDC Industrial Estate, Phase-1, Vatwa, Ahmedabad – 382445, Gujarat, India

Total Area: 76,000 Sq. ft.

Certifications: AS9100D & ISO 9001:2015 Certified for Aerospace, Power, and Engineering Applications.

Capabilities: CNC & Conventional Machine Shop, Raw Material Storage, Dedicated Inventory Area per Client,

Proper Component Preservation and Implementation of Risk, Project & Configuration Management Systems.

Contact: +91-79-49003636 / 3737

| Sr. No. | Name / Description | Type (CNC / VMC / 5-Axis / Manual) | Make & Model | Specifications | Year of Make |

|---|---|---|---|---|---|

| VMC Machines | |||||

| 1 | VMC Machine | VMC 5-Axis | BFW – Chakra (Fanuc Controller) | X1050 × Y610 × Z610 mm, 24 Tools | 2018 |

| 2 | VMC Machine | VMC 3-Axis | BFW – Sooraj (Fanuc Controller) | X1280 × Y700 × Z650 mm, 24 Tools | 2018 |

| 3 | Vertical Machine Center | VMC 3-Axis | COSMOS CVM-800 | X800 × Y500 × Z500 mm | 2020 |

| 4 | VMC Machine (4+1 Axis) | VMC 5-Axis | COSMOS CVM 1060 | Table 1050 × 610 × 510 mm, 24 Tools | 2014 |

| CNC Turning Machines | |||||

| 5 | CNC Turning | CNC | LMW Smart Turn | Max Dia 200 mm × Length 300 mm | 2020 |

| 6 | CNC Turning | CNC | BFW Orbitor | Max Dia 200 mm × Length 300 mm | 2020 |

| 7 | CNC – Super Jobber-LM | CNC | ACE | Dia 200 mm × Length 400 mm | 2010 |

| 8 | CNC – Jobber-XL | CNC | ACE | Dia 250 mm × Length 250 mm | 2012 |

| 9 | CNC Turning | CNC | PMT | Dia 165 mm × Length 230 mm | 2024 |

| 10 | CNC Turning | CNC | PMT | Dia 165 mm × Length 230 mm | 2024 |

| 11 | CNC Turning | CNC | LMW (Siemens Controller) | Dia 165 mm × Length 230 mm | 2024 |

| Honing Machines | |||||

| 12 | Honing Machine | Honing | Tulsi | Stroke 225 mm, ID 20–25 mm | 2020 |

| 13 | Honing Machine | Honing | Tulsi | Stroke 225 mm, ID 20–25 mm | 2020 |

| 14 | Honing Machine | Honing | Tulsi | Stroke 225 mm, ID 20–25 mm | 2020 |

| 15 | Honing Machine | Honing | Tulsi | Stroke 300 mm, ID 30–35 mm | 2020 |

| 16 | Honing Machine | Honing | Tulsi | Stroke 300 mm, ID 30–35 mm | 2020 |

| 17 | Honing Machine | Honing | Tulsi | Stroke 300 mm, ID 30–35 mm | 2024 |

| 18 | Honing Machine | Honing | Tulsi | Stroke 300 mm, ID 30–35 mm | 2024 |

| 19 | Auto Honing Machine | Honing | KMT | Stroke 300 mm, ID 30–35 mm | 2024 |

| Centreless Grinding Machine | |||||

| 20 | Centreless Grinding Machine | C’less Grinding | HILIFE (HLC-150-S) | Max/Min Ø100 / 5 mm | 2021 |

| Conventional / Special Purpose Machines | |||||

| 21 | Heavy Duty Panther Lathe Machine | Lathe | Gujarat Lathe Mfr. Ltd. | 24″ Center Height × 12 ft Bed | 2005 |

| 22 | Heavy Duty Center Lathe Machine | Lathe | RAVI | 12″ Center Height × 8 ft Bed | 2010 |

| 23 | Medium Duty Center Lathe | Lathe | MAXCUT | 8″ Center Height × 6 ft Bed | 2010 |

| 24 | Radial Drill Machine | Radial Drill | BOTLI BOI | 1½” Drilling Capacity | 1996 |

| 25 | Pillar Drill Machine | Radial Drill | GPM | ¾” Drilling Capacity | 1992 |

| 26 | Pillar Drill Machine | Radial Drill | GPM | ¾” Drilling Capacity | 1992 |

| 27 | Pillar Drill Machine | Pillar Drill | SKI | ¾” Drilling Capacity | 1992 |

| 28 | Bandsaw Machine | Cutting | LAXON | Ø180 mm Cutting Capacity | 2010 |

| 29 | Slotting Machine | Manual SPM | BHAVYA BYS-8/20 | Slot Width 20–28 mm | 2013 |

| 30 | Tool Grinder (Bench Type) | Grinder | PANCHAL | ½ HP Motor | 1992 |

| 31 | Heavy Duty Panther Lathe Machine | Lathe | Gujarat Lathe Mfr. Ltd. | 24″ Center Height × 12 ft Bed | 2018 |

| 32 | High Precision Roto Turn Lathe | Lathe | RAVI | Bed Length 7″, Centre Height 12″ | 2022 |

| Utility / Other Machines | |||||

| 33 | Central Compressor | Compressor | CP – Model CPB 25 | 105 CFM, 25 HP Motor | 2018 |

| 34 | Manual Compressor | Compressor | Ari Marshal | 14.0 CFM Capacity | 2013 |

| 35 | Manual Compressor | Compressor | Industrial Engg. | 14.0 CFM Capacity | 2004 |

| 36 | Profile Projector | Profile Projector | Mitutoyo PJ-3000 | Measuring Window X100 × Y100 mm | 2024 |

| 37 | CMM (Inspector Model) | CMM | Hexagon Metrology | Measuring Window X600 × Y800 × Z600 mm | 2014 |