Bangalore Facility

Dedicated Aerospace & Turbine Blade Hub

Our Capabilities

Certifications

AS9100D Certification for Aerospace Manufacturing

ISO 9001:2015 Certification for Quality Management

DGAQA Certification – Registered Defence Vendor (Ahmedabad Unit)

IBR Certification for Cast Valve Manufacturing

India Offset Partner (MoD) – Listed under Partner ID #132

The Bangalore facility integrates advanced machining systems with cutting-edge inspection and measuring technology, designed for high-precision production of Aerospace, Defence, and Energy components.

Overview

Our Bangalore Facility—spanning 15,000 sq. ft. at Peenya Industrial Area, Phase 3—is a precision-driven manufacturing unit of Jasubhai Engineering Pvt. Ltd. – JADE Division.

This facility is ISO 9001:2015 and AS9100D certified, meeting stringent global standards for Aerospace, Defence, and Energy manufacturing. The Bangalore plant serves as a center for high-accuracy machining, assembly, and component validation.

Key Highlights:

CNC & Conventional Machine Shop (Milling, Turning, Turnmill, Grinding, EDM, CMM)

Equipped with Zeiss Spectrum Plus CMM and VMM systems

Controlled environment for component preservation

Advanced risk, project, and configuration management systems

Expert workforce specialized in multi-axis and complex machining

Infrastructure Overview

Vertical Turning Centre – CNC Control

Swing Diameter: 2000 mm | Height: 1700 mm

The Vertical Turning Centre (CNC Control) at our Bangalore facility enables precision turning of large-diameter components with exceptional accuracy and surface finish.

This machine is central to JADE’s ability to manufacture heavy-duty aerospace and defence components requiring complex geometric control.

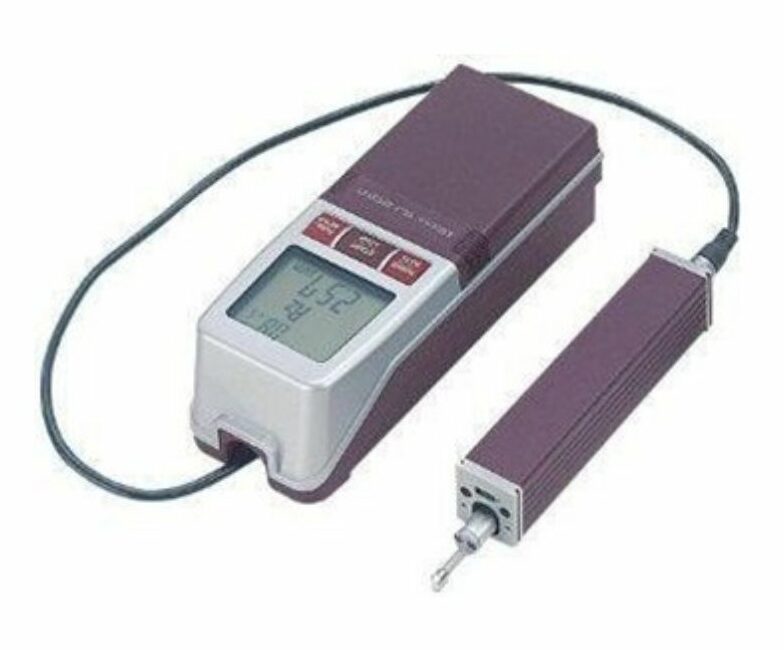

Quality Control: CMM & NDT Testing

These systems ensure zero-defect production and full compliance with AS9100D inspection standards.

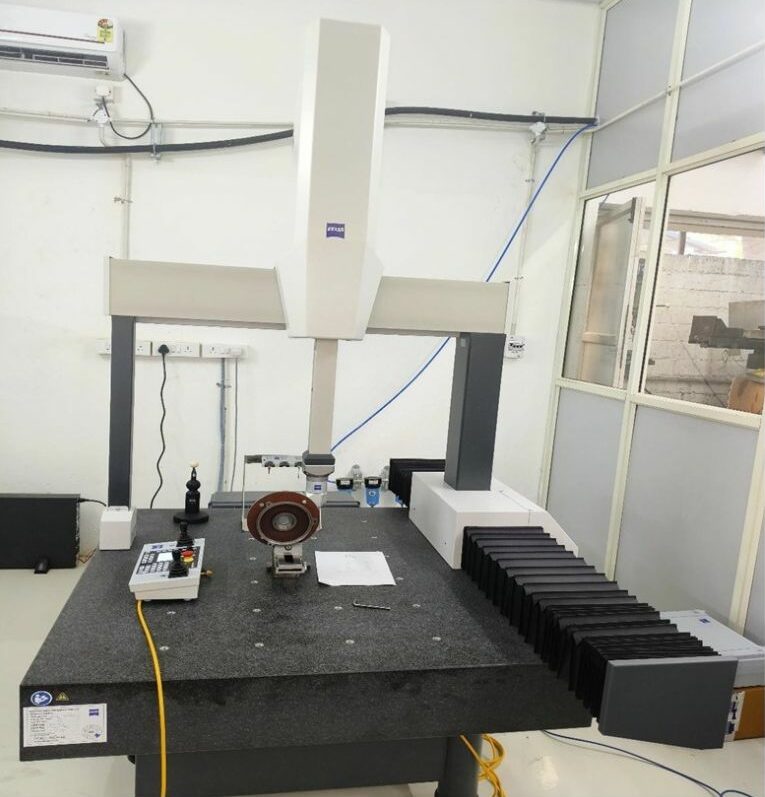

CMM Zeiss Spectrum Plus

Our Zeiss Spectrum Plus Coordinate Measuring Machine is the benchmark of precision inspection within JADE.

It offers superior repeatability, probing accuracy, and 3D geometric validation essential for aerospace and defence components.

CMM Specification:

Measuring Range: 700 × 1000 × 600 mm

Accuracy: ±1.7 µm + L/333

Fully programmable with real-time 3D scanning capability.

Our Machinery: DMG MORI 5-Axis, VMC & Turning Centers

Total Area: 15,000 Sq. ft.

Certifications: ISO 9001:2015 & AS9100D Certified

Capabilities: CNC & Conventional Machine Shop (Milling, Turning, Turnmill, Grinding, EDM, CMM)

Equipped with CMM & VMM facilities, risk and project management systems, and proper component preservation methods.

| LIST OF MACHINES FOR BLADE MACHINING | ||||

|---|---|---|---|---|

| Sl. No. | Machine | Make | Sizes | Operation |

| 1 | VMC 4 AXES | AMS | 800x450x450 | MILLING |

| 2 | VMC 4 AXES | AMS | 1100x500x500 | MILLING |

| 3 | VMC 4 AXES | HASS | 700x400x400 | MILLING |

| 4 | VMC 4 AXES | DAHLHI | 650x400x400 | MILLING |

| 5 | VMC 4 AXES | BFW | 600x400x400 | MILLING |

| 6 | VMC 4 AXES | BFW | 800x400x400 | MILLING |

| 7 | VMC 4 AXES | LOKESH | 700x450x450 | MILLING |

| 8 | VMC 4 AXES | LOKESH | 700x450x450 | MILLING |

| 9 | VMC 3 AXES | AMS | 740x450x450 | MILLING |

| 10 | TURNNMILL 5 AXES | DMG MORI | Dia500x800L | MILLING |

| 11 | TURNNMILL 5 AXES | DMG MORI | Dia500x800L | MILLING |

| 12 | CNC LATHE | LOKESH | Dia250x400 | TURNING |

| 13 | CNC LATHE | LMW | Dia250x400 | TURNING |

| 14 | CNC LATHE | LMW SMART TURN | Dia200x350 | TURNING |

| 15 | VTL | SCHIESS | 2000x1800x1600 | TURNING |

| 16 | VMC 5 AXES + 1 AXES | PVM | 1000x620x630 | MILLING |

| 17 | HMC | AMS 400 XL PLUS | 600x450x420 | MILLING/FITREE SHROUD |

| 18 | GRINDING | AVRO | 600×250 | PITCH GRINDING |

| 19 | GRINDING | ALEX | 1000×300 | PITCH GRINDING |

| 20 | EDM WIRECUT | CONCORD | 250x250x200 | SHROUD WIRECUT |

| 21 | EDM WIRECUT | EXCON | 300x250x250 | SHROUD WIRECUT |

| 22 | Centrelss Grinding | HILIFE (HLC 150 S) | Max/Min dia 125/2mm | GRINDING |

| 23 | Vibro tumbling polishing Machine | JEET | 300 Litre | SUPER POLISHING |

| 24 | Band saw | Vijaya machine tool | Dia225 steel master | For bar cutting |

| 25 | CMM | Zeiss Spectrum Plus | 700x1000x600 | MEASUREMENT |

| 26 | Polishing Machine | POLISHING | EXTERNAL | POLISHING |

| 27 | Polishing Machine | POLISHING | INTERNAL | POLISHING |