Defence Engineering Solutions

Missiles, Naval & Land Systems

DGAQA Approved Defense Manufacturing Facility

Jasubhai Engineering (JADE) is a strategic partner in India’s defense sector, providing world-class Defence Engineering Solutions for mission-critical applications. As a DGAQA-approved facility, we support the indigenization of complex technologies for Land Systems, Naval Defence, and Aerospace applications.

Our Capabilities in Defence Engineering We deliver integrated Defence Engineering Solutions that cover the entire manufacturing lifecycle—from heavy fabrication to precision final assembly.

-

Land Systems: Manufacturing structural sub-assemblies for self-propelled artillery and armored vehicles.

-

Naval Defence: Precision machining of Super Rapid Gun Mount (SRGM) components and heavy naval structures.

-

Missile Systems: Development of high-precision airframe sections and launchers.

Why Choose JADE for Defence Projects?

Executing Defence Engineering Solutions requires more than just machinery; it demands strict adherence to military standards. JADE’s facilities in Pune and Ahmedabad are equipped to handle exotic materials like Armored Steel and Titanium, ensuring that every component meets the rigorous demands of the Indian Armed Forces.

Strategic Manufacturing for Indian Defence components

GUN TRAVEL LOCK (GTL) ASSEMBLY

Overview:

We supplied a complete Gun Travel Lock Assembly consisting of 64 precision-engineered components, including bar stock, castings, sheet metal parts, rubber elements, and imported MIL-SPEC fasteners. The assembly involved special processes like plating and painting, third-party inspections at key stages, integration of all sub-components, and functional testing to ensure full compliance with stringent quality standards before dispatch.

DEFENCE COMPONENTS SUPPLY TO INDIAN PSUs

Overview:

We manufacture critical 5-axis components with tight tolerances for defence system applications. Using advanced CNC machining and CMM inspection, we ensure precision, repeatability, and full compliance with geometric specifications.

Indigenization of Super Rapid Gun Mount (SRGM) Components

Overview:

Manufactured heavy defence components with critical welding requirements and high-precision profile machining, while maintaining metallurgical integrity and structural balance. Achieved precise weld profiles and consistent dimensional accuracy for demanding defence applications.

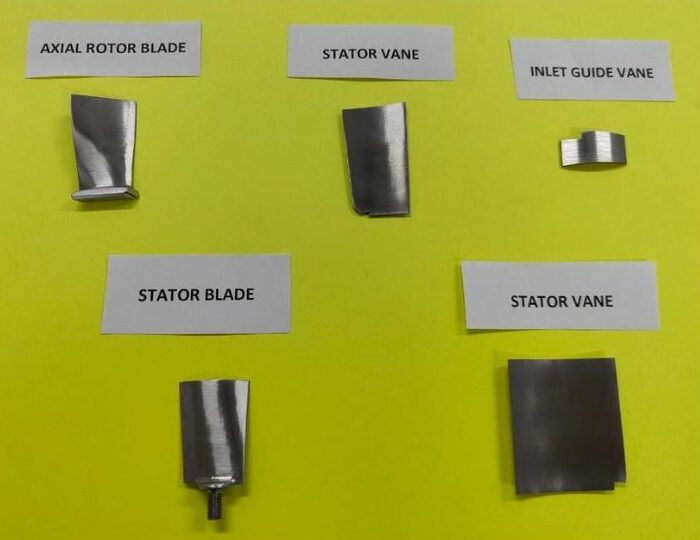

GAS TURBINE BLADES – DEFENCE SECTOR

Overview:

Machined and supplied critical gas turbine blades featuring complex negative-angle profiles and thin-section geometry. Super-finishing techniques ensured consistent high quality across every batch, supporting reliable performance in missile propulsion systems.

Critical Sub-Assemblies for Artillery & Armored Vehicles

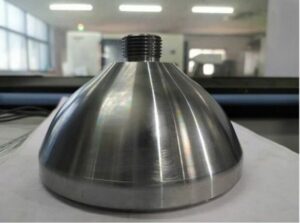

UPPER PART

A precision spherical component with a radius of 67.20 mm and a thickness of 86.80 mm, made from SS304, was manufactured with strict tolerances. Using a custom inner-sphere clamping fixture, ovality was eliminated, and uniform wall thickness of 5.7 mm was maintained, achieving a diameter of 134.4 ± 0.05 mm. The component was delivered on time, fully meeting all quality specifications.

FRONT BOTTOM PLATE

A precision SS304L component measuring 1160 × 2251.5 × 55 mm was manufactured with a surface roughness of N7 and parallelism of 0.1 mm over its 1160 mm length using milling. Optimised CAD programming and precision tool-path control ensured high flatness and surface uniformity, exceeding defence quality standards.

DEFENCE COMPONENTS SUPPLY TO OVERSEAS

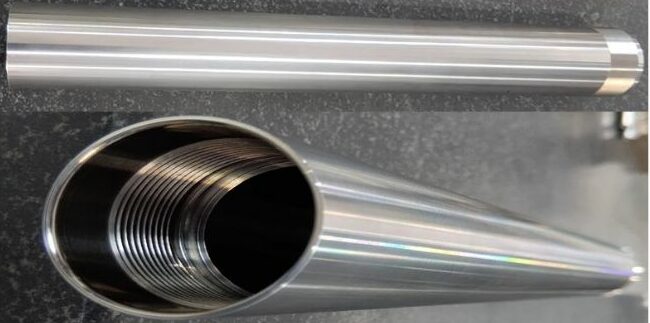

Product: Damper Rod

A precision SS304 annealed cold-rolled bar (ASTM A479) with a maximum size of Ø11.10 mm × 222 mm was manufactured featuring an inner 10-32 UNF 2B thread and an outer 5/16″-24 UNF 2A thread. The component was finished to maintain an OD of 11.10 mm with a surface roughness of Ra 0.2 (N4) max, ensuring high precision and quality compliance.

Product: Damper Housing

A precision SS304 component in annealed condition (ASTM A269) with a maximum size of Ø38.1 mm × 285.8 mm was manufactured featuring an inner 1 3/8″‑20 UN‑2B thread and outer 1 1/2″‑28 UN‑2A thread. Honing was performed throughout the ID of 32.06 mm, achieving a surface roughness of Ra 0.4 (N5) max and maintaining uniform roundness on both ID and OD.

Product: Damper Block

A precision Aluminum Bronze component (ASTM B150 C63000 / AMS4640) with a maximum size of Ø32 mm × 21 mm was manufactured to exacting tolerances. Critical features included perpendicularity ≤ 0.01 mm, flatness ≤ 0.01 mm, concentricity ≤ 0.02 mm, circularity ≤ 0.03 mm, and a surface finish of Ra N5 max, ensuring high precision and compliance with stringent standards.

Strengthening India’s Defence Manufacturing Capabilities

Partner with JADE to manufacture mission-critical components that power the nation’s most advanced defence systems. Together, we drive precision, performance, and progress.