Precision Manufacturing for Energy

Steam Turbines & Nuclear Components

Precision Engineering to Power Industries

Machining of Steam Turbine Blades & Nimonic Alloy Parts

At JADE Energy, we specialize in precision machining and assembly of critical components for the renewable and power generation industry.

Our focus on dimensional accuracy, surface finish, and consistent supply has made us a trusted partner for leading Indian and international energy companies.

Key Projects & Capabilities

TURBINE BLADES MACHINING FOR RENEWABLE ENERGY PSU’s

Overview:

Precision steel X20 Cr13 steam turbine blades were manufactured with complex negative-angle profiles and super-finished surfaces to ensure high-efficiency turbine operation. Multi-axis machining and advanced polishing techniques delivered defect-free blades with consistent geometry and finish across large batches, supporting reliable supply to renewable energy clients and contributing to India’s clean energy initiatives.

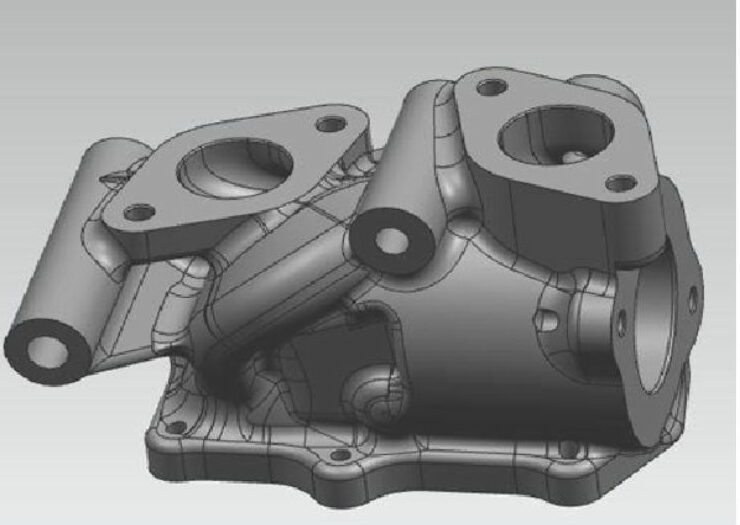

CRITICAL COMPONENTS – MIXING UNIT

Overview:

A precision mixing unit measuring 140 × 87.7 × 103 mm, made from EN 1706 aluminium alloy, was manufactured with a highly complex structural geometry. Using a specialised fixture, machining was completed in just two setups, achieving tight geometric tolerances and an H7 finish on a Ø13 mm × 66 mm hole. The result was a component with exceptional surface quality and dimensional stability, fully meeting stringent performance standards.

Rotor Blade

The blades are angled to direct the force of the steam tangentially, creating a turning force on the rotor

Rotor blades are made from exotic materials with heat-resistant alloys and high-strength materials. 12-stage rotor blades in a turbine are a set of 12 stages of rotating blades to extract energy

Nimonic Blade

Maintains hardness of 32 HRC at high temperatures; low thermal conductivity and rapid tool wear.

Smart Turbine Fan Blade

Initially machinable, it becomes harder post-hardening; precise profile thickness required (20 microns).

Industrial Valve Manufacturing & Testing

Manufacture, assemble, paint, and test industrial valves (sizes 1/2” to 4” / DN15–DN100) in materials like cast iron, carbon steel, and stainless steel. Serves domestic and international markets.

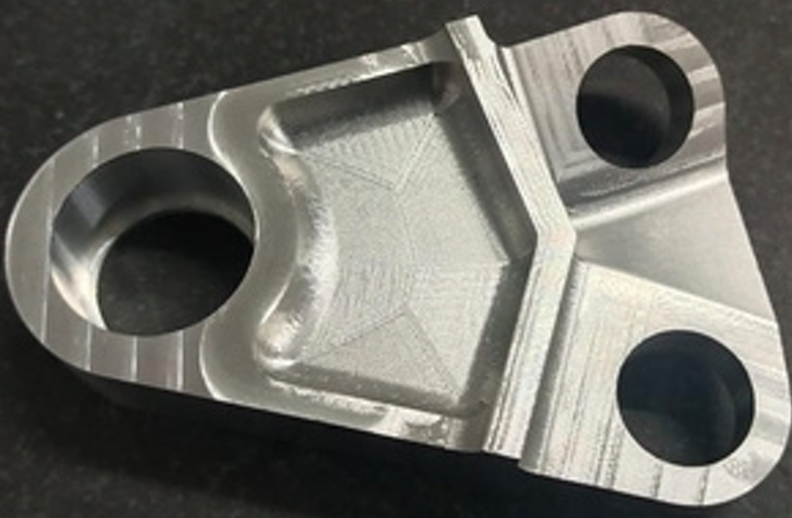

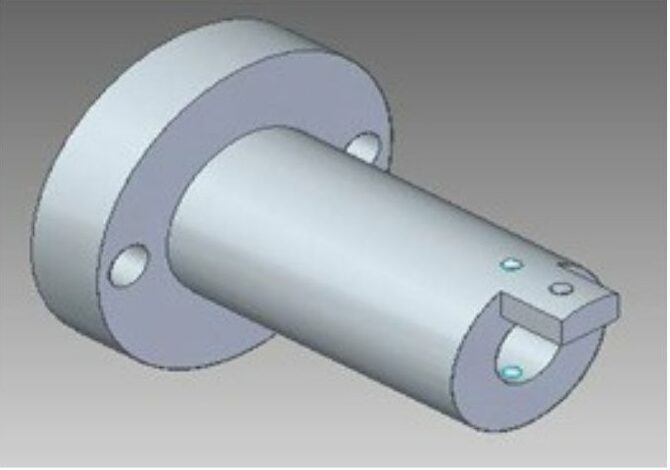

Manufactured from EN8, this drill jig fixture has a maximum size of Ø25 mm × 50 mm, engineered for precision and durability in energy-sector applications.

We manufacture high-precision bar stock components in a wide range of materials including SS, MS, Hastelloy C, Inconel, Titanium, Brass, Aluminium, Tool Steel, and Copper. Components range in diameter from 5 mm to 200 mm and lengths from 10 mm to 1000 mm, meeting stringent energy-sector quality and performance requirements.

Manufactured from C.I Gr. 250, SG Iron, and SS 316L (Investment Casting), these dome valve assemblies are available in diameters ranging from 50 mm to 400 mm, engineered for precision and reliable performance in energy-sector applications.

Manufactured from C.I BS:1452 Gr. 250, these gear box assemblies are precision-engineered from multiple components to ensure reliable performance and durability in energy-sector applications.

Manufactured using SS410, SS431, and Bronze, these valve internal assemblies are precision-engineered from multiple components to ensure reliable performance and durability in energy-sector applications.

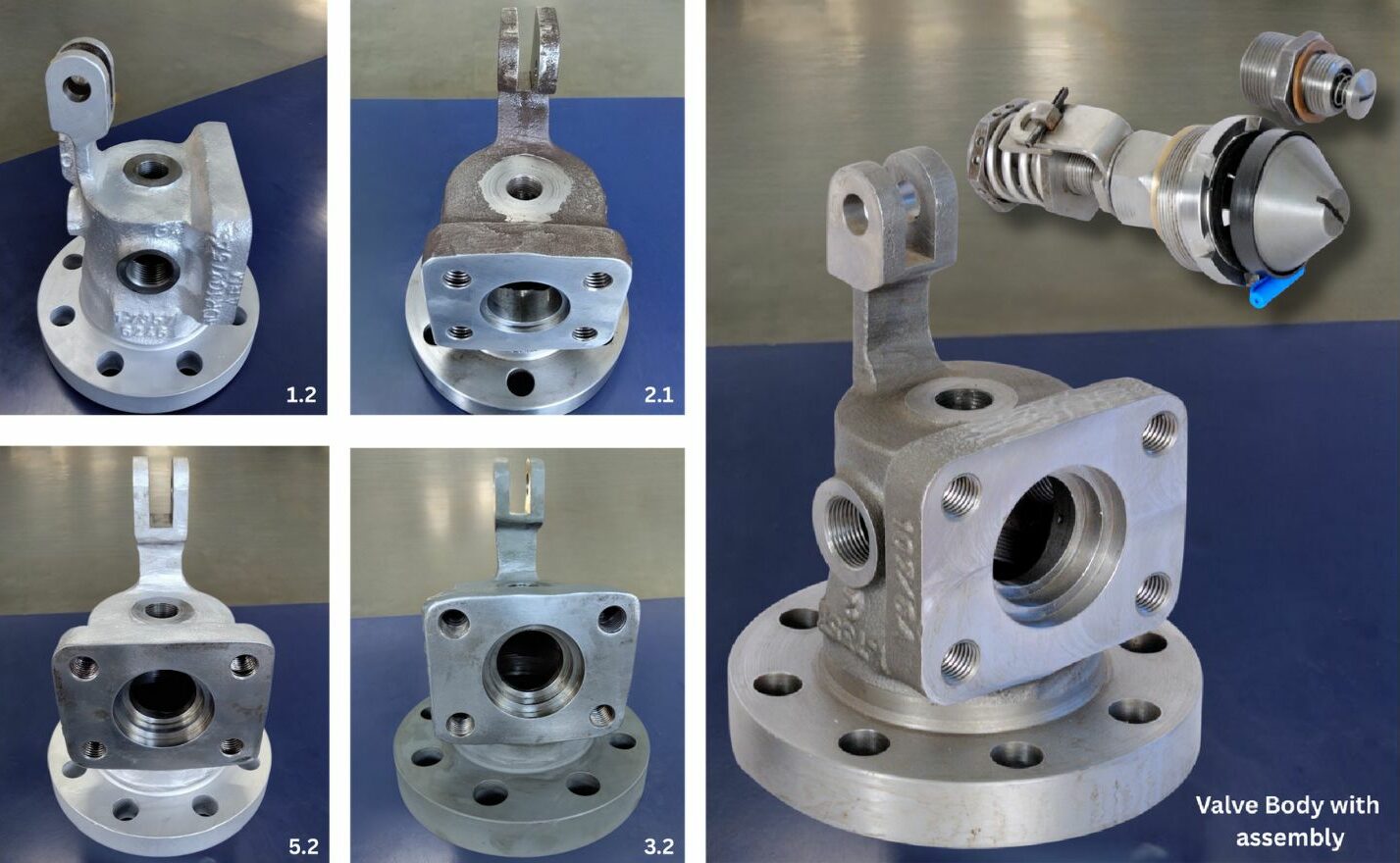

Different Types / Sizes of Valve Bodies with Assembly

Valve Body Assemblies

Overview:

The valve body assemblies are manufactured using CI, SG Iron, SS316L, SS410, and Bronze, ensuring exceptional strength and corrosion resistance. Each component is produced through advanced CNC and 5-axis machining, followed by precise drilling, tapping, and pressure testing to guarantee reliability and performance. Every valve body undergoes hydro, pneumatic, and leak testing as per global standards to ensure zero-defect quality. These assemblies are widely used in power generation, conveying systems, and process automation applications, meeting the stringent requirements of industrial and energy sectors.

Investment Casting & Sand Casting Parts

Cast & machined Components

Overview:

The investment casting and sand casting parts include precision-engineered components such as right-angle elbow joints, cases, cable entry sleeves, pressure gaps, and electronic housings. Each part is manufactured with high dimensional accuracy and superior surface finish using advanced casting techniques. These components are designed to meet stringent mechanical and performance requirements, ensuring durability and reliability in demanding industrial environments.

sand cast components

Overview:

The investment casting and sand casting parts include a diverse range of precision components such as steam chests, connecting rods, body blower carriages, hubs, and brush components. These parts are manufactured using high-quality casting materials and advanced foundry techniques to ensure exceptional strength, dimensional accuracy, and surface finish. Designed for demanding industrial environments, each component undergoes rigorous machining and inspection processes to meet exact specifications and ensure reliable, long-term performance.

High-Precision Casting Components

Overview:

The investment casting and sand casting parts include precision-engineered components such as dome valve bodies and RKS housings, manufactured to meet high-performance industrial requirements. Produced using advanced casting and machining processes, these parts offer superior dimensional accuracy, durability, and corrosion resistance. Each component undergoes stringent quality checks to ensure reliable performance in demanding applications across energy, material handling, and process industries.

Engineering the Future of Energy with Precision

Partner with JADE to deliver reliable, high-performance energy and industrial components that meet the most demanding industry standards.